Flange facing machine safety operation guide

In our daily industrial production, flange facing machine, as an efficient and widely used mechanical equipment, plays an extremely important role. However, like any other mechanical equipment, its use is also accompanied by certain risks. Mastering the safe use of flange facing machine is not only an important prerequisite for ensuring the smooth progress of production, but also the key to ensuring the life safety of operators.

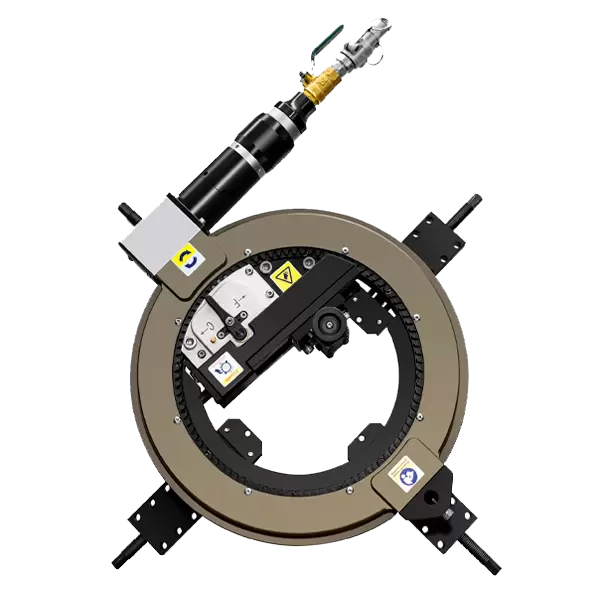

Flange facing machine is a kind of equipment used to process flange end faces. Its main functions include drilling, tapping, milling and other operations on flanges, and it is widely used in petroleum, chemical, shipbuilding, electric power and other fields. Since its operation involves high-speed rotating tools and workpieces, safety accidents are very likely to occur if the operation is improper. Therefore, understanding and strictly abiding by the safety operating procedures are basic skills that every operator must master.

Before starting to operate the flange facing machine, adequate preparation is essential. The operator needs to comprehensively check all aspects of the equipment to ensure that the equipment is in good condition. In particular, attention should be paid to whether the power cord, plug, and socket are intact, whether the voltage and frequency meet the equipment requirements, whether the various parts of the equipment are complete, and whether the fasteners are loose. In addition, it is also necessary to check the use of cutting fluid and lubricating oil to ensure that they are sufficient and of qualified quality. Only when all preparations are completed can the next step be performed.

During the operation, the operator must strictly follow the safety operating procedures. First of all, personal protective equipment, such as protective glasses, earplugs, protective gloves, etc., must be worn to prevent chips, noise and high temperature from causing harm to the person. Secondly, when the equipment is running, it is strictly forbidden to touch the rotating parts or workpieces with your hands to prevent being involved in the equipment and causing harm. At the same time, be careful when loading and unloading workpieces to avoid bumping into equipment or personnel. In addition, the operator should pay attention to the operating status of the equipment at all times, and immediately stop the machine for inspection and repair if any abnormality is found. In particular, when cleaning the equipment or replacing the tool, be sure to cut off the power supply and wait until the equipment stops completely before operating.

In addition to complying with the operating procedures, maintenance and maintenance of the equipment is also an important part of ensuring safe use. Flange end machine requires regular maintenance and maintenance, including cleaning chips and dust inside and outside the equipment, checking whether the electrical circuit and grounding wire are safe and reliable, checking whether the fasteners are loose, and whether the lubricating oil in the lubrication parts is sufficient. Through regular maintenance and care work, potential safety hazards can be discovered and eliminated in time to improve the reliability and safety of the equipment.

In actual operation, operators also need to pay attention to some specific safety matters. For example, when installing the tool, be sure to install the tool handle firmly and ensure that the connection between the tool and the flange end face machine is reliable; during the processing, pay attention to adjusting the cutting parameters such as spindle speed, feed speed and cutting depth to ensure processing quality and safety; when replacing the workpiece, ensure that the workpiece is firmly fixed and avoid collision with other parts to cause damage or injury; when the equipment fails, contact professionals in time for maintenance and troubleshooting, and do not dismantle or repair the equipment privately.

Accident emergency treatment:

If a fire accident occurs during the use of the flange end face machine, the power supply should be cut off immediately and a fire extinguisher should be used for fire fighting. At the same time, report to the superiors and relevant departments to assist in fire fighting and rescue work. When the fire cannot be controlled, the scene should be evacuated quickly and the fire alarm should be called.

If the operator is mechanically injured during the use of the flange end face machine, the machine tool should be stopped and the power supply should be cut off immediately. For minor abrasions or cuts, simple hemostasis and disinfection can be performed; for serious injuries, the patient should be sent to the hospital for treatment immediately. At the same time, report to superiors and relevant departments to assist in accident investigation and handling.

If the flange facing machine has an electrical fault that causes it to fail to operate normally or there is a safety hazard, the power supply should be cut off immediately and reported to superiors and maintenance departments. Maintenance personnel should troubleshoot and repair the fault to ensure that the equipment can continue to be used only after it resumes normal operation.

In short, the safe use of the flange facing machine requires operators to start from multiple aspects, including understanding the performance and purpose of the equipment, making preparations before operation, strictly abiding by safety operating procedures, regularly maintaining and servicing the equipment, and paying attention to some specific safety matters. Only in this way can we ensure that the safety performance and reliability of the flange facing machine during use will escort the safe production of the enterprise.

As an exporter of flange facing machines, we are well aware of the importance of safe use. In the design, manufacturing and testing of products, we always put safety first to ensure that every equipment meets international safety standards. At the same time, we also provide detailed operating manuals and training services to help customers use and maintain equipment correctly and reduce risks and hidden dangers. We are committed to providing customers with high-quality, safe and reliable flange facing machines to help global industrial production safety and efficiency.

https://www.nodha.com/

NODHA Industrial Technology Wuxi Co., LTD

Post Comment