Ensuring Safety and Performance: Comprehensive Medical Balloon Testing Services

Medical balloons are critical components in various minimally invasive procedures, including angioplasty, stent deployment, and occlusion therapies. Ensuring their safety, reliability, and performance is essential for successful clinical outcomes. This article explores the comprehensive testing services available for medical balloons, focusing on key tests such as the balloon leakage test.

Comprehensive Medical Balloon Testing Services

1. Balloon Leakage Test

One of the most critical tests for medical balloons is the leakage test, which ensures that the balloon remains intact and free from defects under pressure. This test is typically conducted using hydraulic burst leak testers, which apply a controlled pressure to detect any leaks or weaknesses in the balloon material. For example, the LSST-04 Balloon Fatigue Tester is designed to assess freedom from leakage and damage on inflation, ensuring that the balloon meets ISO 10555-4 standards.

2. Burst Pressure Testing

Burst pressure testing is essential for determining the maximum pressure a balloon can withstand before rupture. This test helps establish the rated burst pressure (RBP), a key metric for evaluating balloon safety and performance. Modern testers, such as the Crescent Design HBLT™ Hydraulic Burst Leak Tester, provide precise measurements and data recording to ensure compliance with standards.

3. Fatigue Testing

Fatigue testing evaluates the balloon's ability to withstand repeated inflations and deflations without failure. This is particularly important for procedures requiring multiple cycles of expansion and contraction. Tests are often conducted using specialized equipment to simulate real-world use conditions, ensuring the balloon meets the required durability standards.

4. Compliance Testing

Compliance testing measures how the balloon's diameter changes with increasing pressure. This characteristic is crucial for ensuring the balloon expands predictably and uniformly, which is vital for procedures like stent deployment. Compliance tests are typically performed using laser micrometers to ensure precise measurements.

5. Inflation and Deflation Time Testing

This test evaluates the time it takes for the balloon to inflate to its rated pressure and subsequently deflate. Efficient inflation and deflation times are essential for minimizing procedure duration and reducing patient discomfort.

6. Dimensional Verification

Ensuring the balloon meets specified dimensions is critical for its performance and compatibility with other medical devices. Dimensional testing includes verifying the balloon's diameter, length, and wall thickness using precise measurement techniques like non-contact laser thickness gauges.

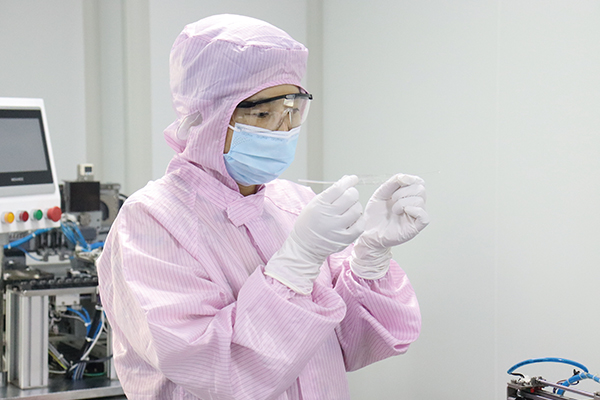

7. Visual Defect Inspection

Visual inspections are conducted to identify any defects, such as tears, pinholes, or irregularities in the balloon material. These defects can compromise the device's integrity and safety. Comprehensive visual inspections are performed throughout the manufacturing process to ensure high-quality standards.

Regulatory Standards and Compliance

Medical balloon testing services are designed to meet stringent regulatory standards. These standards cover a range of tests, including rated burst pressure, balloon fatigue, leakage, and deflation time.

Medical balloon testing is a multifaceted process that involves a range of mechanical, dimensional, and functional evaluations. By leveraging advanced testing services, manufacturers can ensure their devices are safe, reliable, and ready for clinical use.

www.smartballoon.net

SmartBalloon Medical Technology

Post Comment