Technology and Application of Slewing Drive for Aerial Plarform

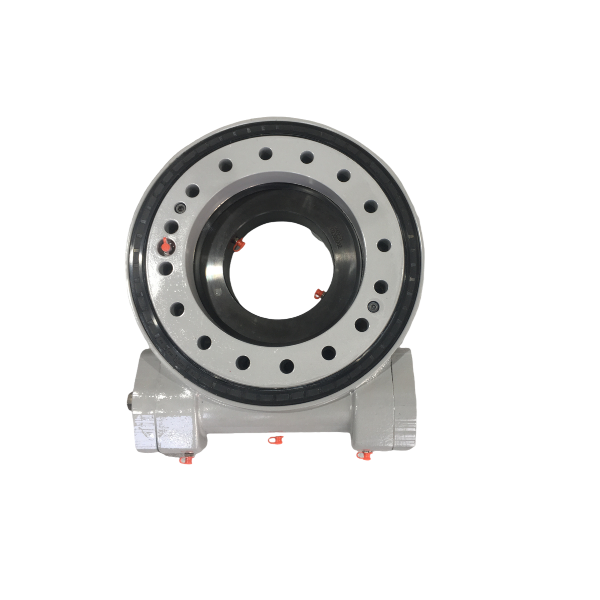

In the rapidly evolving field of aerial platforms, the slewing drive has emerged as a pivotal component, driving innovation and enhancing functionality across various applications. Aerial platforms, encompassing drones, unmanned aerial vehicles (UAVs), and aerial work platforms, rely heavily on the precision and reliability of their slewing mechanisms to execute complex maneuvers and ensure operational efficiency. The slewing drive for aerial plarforms, manufactured by Wuxi UpperPeak Drive Equipment, represents a pinnacle of technological innovation in the aerospace industry. Their expertise in developing high-torque, low-maintenance slewing drives contributes significantly to enhancing the operational efficiency and reliability of aerial systems, pushing the boundaries of what's possible in aerial exploration and applications.

Core Technology of Slewing Drives

1. Gearbox Design

The gearbox is the heart of the slewing drive, responsible for transmitting torque and facilitating smooth rotation. Modern slewing drive for aerial plarforms incorporate high-precision gears, often made from hardened steel, to ensure durability and reduce wear. Helical and planetary gear configurations are common, offering high torque density and efficient power transmission.

2. Motor Integration

Electric motors, particularly brushless DC (BLDC) and permanent magnet synchronous motors (PMSMs), are preferred due to their compact size, high efficiency, and low maintenance requirements. Integration of these motors within the slewing drive allows for precise control and rapid acceleration, critical for agile aerial maneuvers.

3. Sensor Technology

Advanced sensors, such as encoders and gyroscopes, provide real-time feedback on position, speed, and orientation, enabling closed-loop control systems. This enhances the accuracy and stability of aerial platforms, especially in challenging environments like high winds or turbulent airspaces.

4. Lubrication Systems

Efficient lubrication is crucial for reducing friction and wear in slewing drives. Modern systems utilize long-lasting lubricants and self-lubricating materials to minimize maintenance intervals and extend component lifespan.

Key Selling Points

1. High Precision and Reliability

Slewing drive for aerial plarforms are engineered to deliver exceptional precision and reliability. The use of high-quality materials and precision manufacturing techniques ensures tight tolerances and smooth operation, critical for maintaining aerial platform stability and accuracy during missions.

2. Compact Design

Space is a premium in aerial platforms, necessitating compact and lightweight components. Slewing drives have undergone significant miniaturization, combining high performance with a sleek footprint. This enables integration into a wider range of aerial vehicles, from small drones to large unmanned aerial systems.

3. Robust Construction

Operating in diverse and often harsh environments, slewing drives must withstand extreme temperatures, vibrations, and impacts. Robust construction, including reinforced housings and sealed bearings, protects against contamination and ensures continuous performance, even in challenging conditions.

4. Customizable Solutions

No two aerial platforms are alike, necessitating customizable slewing drive solutions. Manufacturers offer a range of configurations, gear ratios, and motor options to tailor drives to specific application needs. This flexibility ensures optimal performance and cost-effectiveness across various platforms.

Applications in Aerial Platforms

1. Drones and UAVs

Slewing drives are instrumental in the gimbal systems of drones and UAVs, enabling stable camera platforms for aerial photography, surveillance, and mapping. The precise control and smooth rotation provided by slewing drives enhance image quality and data accuracy, crucial for professional applications.

2. Aerial Work Platforms

In aerial work platforms, such as cherry pickers and scissor lifts, slewing drives facilitate smooth and controlled rotation of the work basket or platform. This enhances operator safety and efficiency, particularly in confined or difficult-to-access areas.

3. Search and Rescue Missions

Slewing drives play a vital role in search and rescue drones, enabling rapid and accurate scanning of large areas. The precision and reliability of these drives ensure that critical information is captured and transmitted in real-time, aiding in timely response and rescue operations.

4. Agricultural Monitoring

In agriculture, drones equipped with slewing drives enable precise crop monitoring and pest control. The ability to adjust the camera angle and zoom level on-the-fly provides farmers with detailed insights into crop health and yield potential, driving informed decision-making.

Conclusion

The technology and application of Wuxi UpperPeak Drive Equipment slewing drive for aerial plarforms are continually evolving, driven by the need for higher precision, reliability, and customization. By integrating advanced gearbox designs, motor technologies, and sensor systems, slewing drives are enabling a new era of aerial platforms capable of performing complex missions with unprecedented accuracy and efficiency. As the industry continues to grow, the development of innovative slewing drive solutions will remain crucial in pushing the boundaries of aerial capabilities.

https://www.uppdriver.com/technology-and-application-of-slewing-drive-for-aerial-plarform.html

www.uppdriver.com

无锡上锋传动设备有限公司

Post Comment